As you will see in the video – the whole family is ill right now! This Greek Lemon Chicken Soup is a nourishing, delicate recipe that punches with flavour and hopefully makes everyone in my house better! This recipe calls for couscous, but you can replace this with quinoa, orzo or larger-format Israeli couscous.

This Moroccan Chicken Couscous is perfect for a school lunch. Served hot or cold, my kids adore every bite.

This Moroccan Chicken Couscous is perfect for a school lunch. Served hot or cold, my kids adore every bite.

50g pine nuts (leave out if your school has nut allergies)

500g chicken breast or thigh fillet, cut into 2cm dice

1/4 cup flour, seasoned with salt and pepper

3 tbsp olive oil

2 onions, sliced

1 tsp ground cinnamon

1 tsp ground cumin

1 tsp ground mild paprika

1 tsp ground coriander

1/4 cup sultanas

1 cup (250mL) chicken stock

1/4 cup chopped fresh coriander or flat-leaf parsley

1 lemon, juiced

2 cups couscous

2 cups water or chicken stock

1/4 cup diced tomatoes

thick natural yoghurt, to serve

- Heat a large non-stick pan over medium-high heat. Add pine nuts, stirring constantly until just starting to colour. Transfer pine nuts to a plate.

- Place seasoned flour in a large bowl, add chicken and toss to coat. Add one tbsp of oil to the frypan, increase heat to high and cook half the chicken until golden. Transfer cooked chicken to a plate. Repeat with another tbsp of oil and remaining chicken.

- Heat remaining tbsp of oil in pan. Add onions, reduce heat to medium and cook, stirring frequently, for 10 minutes or until golden and softened. Add cooked chicken to frypan with spices, sultanas and one cup of stock. Bring to boil, then reduce heat to low and cook for 5-10 minutes until heated through and thickened. Just before serving, stir in pine nuts, coriander and lemon juice.

- To prepare couscous, bring 2 cups of stock or water to the boil in a small saucepan, stir in couscous and olive oil and turn off heat. Leave for 5 minutes, then use a fork to separate the couscous grains.

- Serve chicken with couscous and yoghurt.

Photo Credit: Irena Macri

Picture this. London, 2011. A big boardroom full of Cargill Employees, the Canadian Food Inspection Agency (CFIA), McDonald’s employees, and 4 absolutely stiff, petrified Moms. And a baby (Mo is so devoted her 3 week-old joined us). We knew how these things worked by now and how this tour would go…. coffee, an intense 3-hour crash course about the industry and how the facility is run, with farming fodder thrown-in and tweets being answered at the same time. Then a lunch. And then. Gasp. A plant tour. (You thought the gasp was for the crazy helmets, lab coats, safety goggles and hairnets, didn’t you?) Unlike our beef and potato plant tours, however, for this tour we were slated to see the… I have trouble saying it. The point at which an alive chicken becomes a not-alive chicken. We were terrified. Why don’t I start at the beginning, though. The chicken. No. The egg. Snicker. (See – I use humour when I’m not quite comfortable).

Picture this. London, 2011. A big boardroom full of Cargill Employees, the Canadian Food Inspection Agency (CFIA), McDonald’s employees, and 4 absolutely stiff, petrified Moms. And a baby (Mo is so devoted her 3 week-old joined us). We knew how these things worked by now and how this tour would go…. coffee, an intense 3-hour crash course about the industry and how the facility is run, with farming fodder thrown-in and tweets being answered at the same time. Then a lunch. And then. Gasp. A plant tour. (You thought the gasp was for the crazy helmets, lab coats, safety goggles and hairnets, didn’t you?) Unlike our beef and potato plant tours, however, for this tour we were slated to see the… I have trouble saying it. The point at which an alive chicken becomes a not-alive chicken. We were terrified. Why don’t I start at the beginning, though. The chicken. No. The egg. Snicker. (See – I use humour when I’m not quite comfortable).

From Egg to Chicken:

The eggs are collected daily from the farms and transported to a hatchery where they are incubated for 19 days. A ‘setter’ constantly turns the eggs to keep them warm and provides a simulation similar to a mother hen sitting on top of them. That revelation kind of validated my role as a mother. Kind of. In a George Orwell kind of way. At the 19-day mark, the eggs are vaccinated and transferred to hatch baskets where they will hatch within 2 days. Once hatched, the chicks are separated from the eggshells and transferred to chicken farms until market age (40-45 days old).

From Chicken to Egg:

I’m completely convinced after meeting the farming experts, regulators, and Cargill employees, that care for the animals really is paramount. Cargill deals with 140 chicken farms and all must meet very rigorous standards as specified by McDonald’s. In Canada, the family farm model is the norm. Having farmers own and care for their chickens until the point at which they are transported from the farm for processing helps ensure the quality and integrity of the farm.

The barns are kept at 28 – 32 degrees celsius and the chickens roam around on shavings. They always have access to feed and water and are free to roam within the barn. Federal regulations in Canada recommend that no more chickens can be in a barn than 31 kilos per meter square. Farm managers and their staff visit the barn throughout the day.

For all of you who are going to ask about ‘free range’ in the barns, the chickens in these barns are just meat birds (broiler chickens). These are very different than egg layers. The broiler chickens are kept in barns to ensure food safety. If these meat birds were outside they would be more susceptible to disease.

Advances in feed for the birds mean that currently, 2 pounds of grain fed to a chicken will produce 1 pound of chicken. The feed is 88 percent grain, 10 percent protein, and 1-2 percent vitamin supplements.

All catchers and drivers are trained in animal welfare practices and as of July 1, 2011, a person must be specially licensed to transport chickens. The live birds are put into crates and the birds must be able to move comfortably. They are on the trucks only 4-8 hours, as most farms are within an hour or 2 of the London Cargill plant. During the warm summer months, the birds are misted to keep them more comfortable in the heat.

From Alive Chicken to Not-Alive Chicken:

In the Cargill plant, 3,200 different food safety and quality checks occur on a daily basis. There are even 2 X-ray machines that detects residual bones or foreign material – and the chicken meat passes through 2-3 times!

I was shocked to hear that 80-90,000 chickens are processed daily. 900 people work at the plant, and only 3 per cent leave the facility each year. Cargill boasts one of the lowest turnover rates for the meat industry in the world.

The facility is separated into the raw chicken processing part and the food manufacturing part. For food safety reasons, employees wash their hands and go through a boot sanitizer and, in addition to regular cleaning, the entire plant is completely cleaned and disinfected nightly by 60 people – like the inside of a dishwasher. I wish my house had that capability.

When the live chickens come into the plant, they are removed from the truck by a human being on a scissor lift to ensure that the employee is at the same level as the crates. This is better for people, to help avoid back problems, as well as the chickens.

In the slaughter area, everyone was so calm and peaceful I didn’t know where I was until it was pointed out to me. It wasn’t what I was expecting. It was very dark, with a blue light shining. As per Temple Grandin’s recommendations on animal welfare (link to beef post), the facility has been audited and Temple Grandin has approved of the process itself. In addition, blue lights are used because birds can’t see the colour blue so it appears dark. They are hung by the ankles, a plate or bar rubs the breast of the bird and they hang touching each other, shoulder to shoulder. I witnessed first-hand how calm this makes the birds. They are not flapping or making noise. They travel on a rounded track and are dipped quickly in water where an electrical stun renders the chicken insensible to pain, which means they are unconscious and alive but do not feel any pain. Their necks are cut and the bleed-out occurs while the chicken is unconscious so they are dead before they wake.

To remove the feathers, the birds go through a hot water bath and pickers – rubber fingers – massage the bird and take out feathers. The head and feet are removed and a machine removes the organs, transferring the viscera to a separate line. The organs and bird are kept together for inspection so that if the inspector and vet condemn a bird, the whole bird will be disposed of – again for food safety. Fifteen federal inspectors, including four CFIA vets work at the London facility. Once the chicken and organs have been inspected and approved, the meat moves on to food processing. Every part of the chicken has a use. The organs are used for pet food and animal feed, while the blood, feathers and offals are sold to a rendering company that makes ingredients for animal feeds, fertilizers and markets such as cosmetics, rubber and explosives.

The bird is placed in a chilling tank for 1 hour and must cool to less than 4 degrees Celsius in order to debone, which means to remove the bones from the meat. Chlorine is present in the chiller for sanitation purposes, much like a swimming pool. Levels are monitored every hour. At this point, an antimicrobial treatment is applied. It is cetylpyridinium chloride – the same substance contained in mouthwash. This is an opportunity to reduce salmonella. The bird is then rinsed. For the record, this is when I relaxed significantly. I was now looking at chickens like I’d buy in a supermarket.

75 per cent of the original bird goes into debone process, and I was shocked at the number of people working together to debone the chickens. By hand. Seriously. Wow. There is no mechanically separated meat in McDonald’s products. The frames of the chicken that are left at the end of the process get sent to another facility for people who use mechanically separated meat for hotdogs and other products.

The Making of McNuggets:

The white breast meat, along with chicken stock and a natural proportion of skin from the breast is placed into a huge blender. I didn’t realize that there is skin in the nugget mixture but this helps to hold the shape. The meat is then mixed and chilled using CO2. McNuggets are formed, not ground. There are 4 shapes that are pressed out with a rolling cookie cutter: boot, bow-tie, ball and bell. The reason they are all standard in shape and size is to ensure consistency in all McDonald’s restaurants. This guarantees both food safety (standard cooking times in restaurants) and portion control.

Once the fun shapes pop out, they are coated in batter, dusted with flour and then given a final coat of tempura batter. Who knew? From here they are par-fried and placed directly into the freezer. A thin mist of water is sprayed onto them, as tempura is susceptible to dehydration. They are then inspected and packaged to be sent off to the restaurants.

Grilled Chicken:

We also witnessed the grilled chicken being made. It’s pretty simple – it’s just one huge hunk of breast meat but a laser-guided water jet cutter trims it to an exact size. Very James Bond.

In all, I will still eat chicken. I will still eat McNuggets. I’m satisfied with the animal treatment and food safety. I think I’ll stick with the grilled chicken in snack wraps and sandwiches, as there are fewer ingredients, but the nuggets sure are yummy! For the other All-Access blogs please click here, or to see the UrbanMommies Q and A, click here.

As with every All-Access trip, our published polls readers for questions and has promised to find the answers. Here they are!

As with every All-Access trip, our published polls readers for questions and has promised to find the answers. Here they are!

Q: What about vaccines, antibiotics and hormones used in chicken products?

A: Vaccines are administered once throughout the chickens’ life to prevent the birds from dying of diseases and improve the health of the whole flock. In order to feed millions of people and remove undue suffering of the animals, McDonald’s and Cargill’s policy is to vaccinate. Antibiotics are only given if a bird tests positive for illness, which would put the entire flock at risk. Antibiotics require a vet prescription and a strict withdrawal period is adhered to before the chicken is turned into food to ensure that no residual medications are present in the product.

McDonald’s has a global antibiotic policy. It is a policy that has been developed with the assistance of scientists and industry experts. Given that McDonald’s is required to process 90,000 birds per day in Canada alone to feed its customers, the company has a keen interest in making sure the industry is sustainable. The pre-emptive use of antibiotics is not allowed, nor does it allow sub-therapeutic use. Even the feedmills that produce the grains fed to chickens have to be accredited and constantly audited.

Hormones are illegal in Canada for use in chicken and in dairy. This is due to the withdrawal period that is required. There is not enough time for hormone elimination in milk and chickens. That’s why there are no hormones allowed. Beef has more time in withdrawal period and is therefore acceptable to use hormones before it is processed for meat production.

Q: People have asked me why there are so many ingredients in McNuggets and why the ingredients are so chemical-sounding?

A: McDonald’s is very careful about listing ingredients for allergy reasons and ingredients that could be bundled together are separated out to help people who may have an allergy. Chemical names are used which might sound more complicated than they are (they say sodium bicarbonate instead baking soda, for instance).

For the full post on chicken please chick here.

About to take off on my final journey I am quite sad, actually. The whole experience as a McDonald’s All-Access Mom has been transformative, but not in any of the ways I expected. Sure – lots of questions have been answered, I’ve traipsed around farms and plants (check out the videos), and worn way too many un-sexy lab coats. But I also feel like a better mom. A better citizen. The corporate culture of McDonald’s and its suppliers is much friendlier – much more transparent, than I was expecting. After almost 6 years of momm-ing, I think I’ve gotten a bit too insular. Charity work had lapsed and a disconnection to the world and it’s news had set in. The opportunity to participate in the MAAM program has helped change that.

About to take off on my final journey I am quite sad, actually. The whole experience as a McDonald’s All-Access Mom has been transformative, but not in any of the ways I expected. Sure – lots of questions have been answered, I’ve traipsed around farms and plants (check out the videos), and worn way too many un-sexy lab coats. But I also feel like a better mom. A better citizen. The corporate culture of McDonald’s and its suppliers is much friendlier – much more transparent, than I was expecting. After almost 6 years of momm-ing, I think I’ve gotten a bit too insular. Charity work had lapsed and a disconnection to the world and it’s news had set in. The opportunity to participate in the MAAM program has helped change that.

I am most excited about seeing the Ronald McDonald House Charities. Giving back. Sharing. Helping. These charities give homes and home cooked meals to families whose children are hospitalized with severe illness. I will be spending a full day with the children and families involved in the London, Ontario house, learning about the program and more importantly, the people. I hope that I can take the lessons of charity and giving back to my own children and incorporate them into our daily lives. I know there has been criticism of the All-Access-Mom program, but this is an opportunity to get a glimpse into something that nobody could say McDonald’s doesn’t do really well.

The second part of the trip? Chicken at the London, Ontario Cargill facility. Shall I cluck like when I moo-ed at the cows? Want to know the deal with the shaped McNuggets? (I already asked about chicken lips and toenails getting into the mix.) Nada. Any other questions? Reconstituted white meat? Glue? Sawdust? Last chance!!

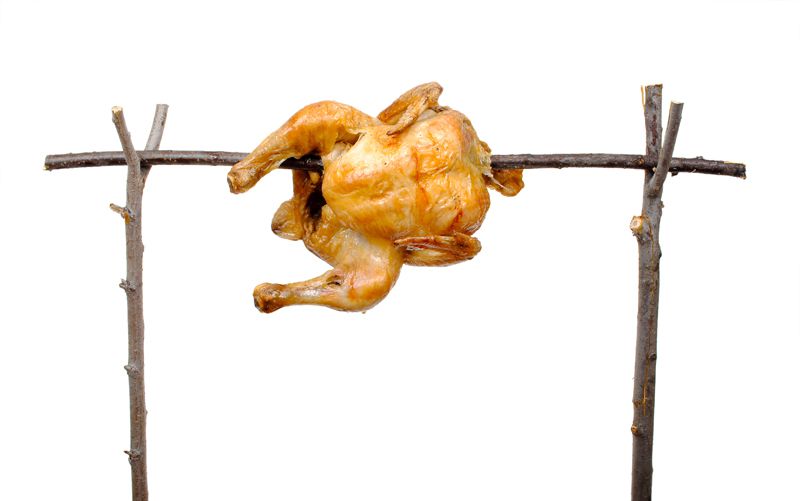

Don’t feel like you have to have attended Cordon Bleu to be able to produce a beautiful meal for your family. Cooking is a lot easier than you think, if you approach it intuitively. There are, of course, a lot of complex things involved in many disciplines (making sauces, baking, etc.), but most moms at home can make absolutely fabulous meals without too much effort. This meal, roasted chicken and veggies, is one of my favorites with the family, plus it’s super-easy to make. Seriously, there are three basic steps to the entire meal. Check our tips for How to Roast the Perfect Chicken at Home. Let’s get started!

Don’t feel like you have to have attended Cordon Bleu to be able to produce a beautiful meal for your family. Cooking is a lot easier than you think, if you approach it intuitively. There are, of course, a lot of complex things involved in many disciplines (making sauces, baking, etc.), but most moms at home can make absolutely fabulous meals without too much effort. This meal, roasted chicken and veggies, is one of my favorites with the family, plus it’s super-easy to make. Seriously, there are three basic steps to the entire meal. Check our tips for How to Roast the Perfect Chicken at Home. Let’s get started!

Craving coriander but can’t quite make it to the grocery store, let alone India? Rent a Bollywood film, don a sari and have a family theme night to teach the kids about far away places. And be healthy at the same time.